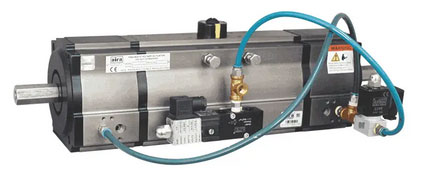

Travel Stopper Pneumatic Actuator

Specification & Standard

Method Of Transmission

Double Acting Adjustable Travel Stopper

Body

Extruded Aluminium Hard Anodized

Caps And Rack

Aluminium Pressure Die Cast

Rotation

0 To 90° Adjustable

Mounting PCD

ISO 5211 Mounting

Piston Material

Aluminium / WCB

Application

Operating For Valve

Features & Benefits

1. Hard Anodized Barrel / Body to Protect from Hazardous atmosphere & corrosion, which enhance life of actuator.

2. Mounting Standard Pinion Top (As Per Namur Standard) The pinion

(shaft) top drilled and slotted for easy assembling of switch, positioners and

other accessories.

3. Adjusting Bolt Adjusting Bolts for 0 – 90° ± 5% Over Travel.

4. ISO – 5211 Standard Mounting for Valve (An International Standard) Double bottom drilling for actuator to valve Assembling & centering. Designed for strength and easy mounting or interchangeability

5. ISO – 5211 Standard Pinion Bottom (An International Standard) Bottom of the pinion (Shaft) as female key, double square-hole for assembling on valves with square key stem and in line or turned to 45O. Designed for strength and sure-fix with stem.

6. Sliding Skates The innovation for replaceable sliding skates, between Pistons (Racks) and internal bore surface of the Actuator, just to avoid metal contact, which enhances the Actuator life.

7. Compact Design “aira” Actuators are designed as compact double acting which offers high torque values. Internal sliding surface, machined and anodized for minimum friction and long life of actuator

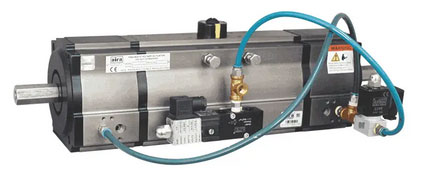

3 Position Pneumatic Actuator

Specification & Standard

Body Material

Extruded Aluminium Hard Anodized

Air Pressure

Normal Air Supply Pressure: 4KG/CM², AIR SUPPLY PRESSURE: 8KG/CM² MAX

Rotation

90° – Quarter Turn

Caps And Rack

Aluminium Pressure Die Cast

Features & Benefits

1. Actuator is suitable for coarse – fine adjustment, typically forbatching operations or processes.

2. The Actuator has to be Double Acting.

3. The repeatability is 100% since stopping is by mechanicalstoppers. It is suitable for application calling for the precise fine-coarse adjustment like liquid filling system.

4. The Actuator can be switched to one, position from any otherposition very easily with the solenoid control. The 3rd positionis achieved by the mechanical stopping of the piston movement,in the return stroke by pneumatic stopper pistons.

5. The Intermediate position is present at 20% opening. Theopening can be adjusted as required by the set screw. This is field adjustable.

6. Actuator as a standard, works in reverse action, as opposed toconventional configuration i.e. piston inward stroke opens thevalve, and piston outward stroke closes the valve.

7. The End Stops (+/- 5°) are provided on the closing and openingside of the Actuator for setting valve closing precisely.

8. 5,00,000 Cycles POD.

Scotch Yoke Single Acting Pneumatic Actuator

Specification & Standard

Mounting PCD

ISO 5211 Mounting Standard

Body Materials

Aluminium - Extruded

Piston Material

Aluminium

Application

Operating For Valve

Features & Benefits

1 – Travel adjustment ±8° for clock wise and counter-clock wise strokes.

2 – Nitrile rubber piston O-rings offer excellent sealing and wear. Optional low and high temperature seals and lube are available.

3 – PTFE Guide Band supports piston while providing smooth operation and extended life.

4 – Extra large, strong piston rod for long life and torque transmission.

5 – Namur accessory mounting pads permit mounting standardization of limit switches, positioners etc.

6 – Ductile iron center body.

7 – Modular design allows for installing power groups and spring cartridges so that actuators may be set up for different air pressures and for Fail Clockwise and Fail Counter-clockwise.

8 – Rugged heavy duty steel pressure cylinders chrome plated for long wear and corrosion resistance.

9 – Safe, welded spring cartridges with numerous options for a broad range of air pressure conditions.

10 – Alloy Steel, corrosion resistant and heat treated springs designed and manufactured for long high cycle life.

11 – Steel slide block, bronze slide bearings to minimize friction and provide long cycle life Visual position indicator.

12 – Carbon steel Scotch Yoke mechanism available in symmetric form.

13 – Totally enclosed weatherproof central body.

Scotch Yoke Double Acting Pneumatic Actuator

Specification & Standard

Size Range

SAY-14 To SAY-60

Temperature Range

-20°C To 90°C

Working Pressure

4 To 7 Bar

Mounting PCD

ISO 5211 Mounting Standard

Body Material

Aluminium - Extruded

Features & Benefits

1 – Travel adjustment ±8° for clock wise and counter-clock wise strokes.

2 – Nitrile rubber piston O-rings offer excellent sealing and wear. Optional low and high temperature seals and lube are available.

3 – PTFE Guide Band supports piston while providing smooth operation and extended life.

4 – Extra large, strong piston rod for long life and torque transmission.

5 – Namur accessory mounting pads permit mounting standardization of limit switches, positioners etc.

6 – Ductile iron center body.

7 – Modular design allows for installing power groups and spring cartridges so that actuators may be set

up for different air pressures and for Fail Clockwise and Fail Counter-clockwise.

8 – Rugged heavy duty steel pressure cylinders chrome plated for long wear and corrosion resistance.

9 – Safe, welded spring cartridges with numerous options for a broad range of air pressure conditions.

10 – Alloy Steel, corrosion resistant and heat treated springs designed and manufactured for long high cycle life.

11 – Steel slide block, bronze slide bearings to minimize friction and provide long cycle life Visual

position indicator.

12 – Carbon steel Scotch Yoke mechanism available in symmetric form.

13 – Totally enclosed weatherproof central body

1 | 2 | 3